Automatic Corn Puff Snacks Production Line

This automatic Corn Puff Snacks Production Line use corn powder, grain flour and other flours as main material, through mixing, extruding,

drying, flavoring and packing, to get flavored corn puffed snacks. It always service as corn puffs mixed with colored agents. This production

system can also many kinds of different shapes of corn puffed snacks, such as rings, balls, curls etc.

|

Name |

Description of automatic Corn Puff Snacks Production Line |

|

Raw material |

Corn flour, rice flour, wheat flour and other barley powder |

|

Basic Recipe |

Grist powder, coco powder, water etc |

|

Processing Flow |

mixing system; Extrusion System; Drying system; packing system |

|

Final products |

Corn puffed snacks with Variety shapes are available, such as ball, stick, ring, fruit loop, star wheel, flower and heart by adjustable the moulds on the extruder. |

Samples made by Automatic Corn Puff Snacks Production Line

Details & Features of our Automatic Corn Puff Snacks Production Line

|

No

|

Model

|

Capacity

|

Power

|

Size

|

|

1

|

SLG65

|

120-150kg/h

|

70KW

|

100㎡

|

|

2

|

SLG70

|

240-250kg/h

|

110KW

|

120㎡

|

|

3

|

SLG85

|

400-450kg/h

|

180KW

|

150㎡

|

Some pictures of our factory

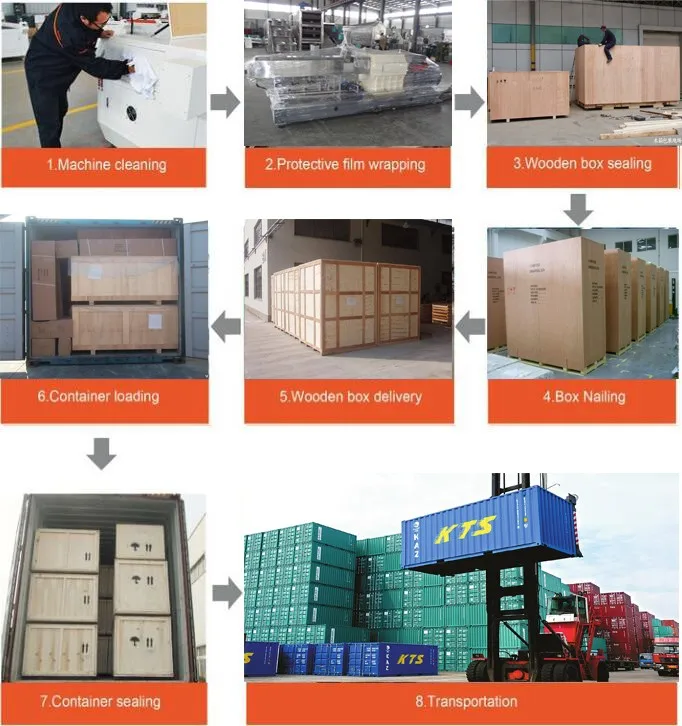

Packing of our Automatic Corn Puff Snacks and other machines

Hot Tags: automatic corn puff snacks production line, China, manufacturers, suppliers, price