In recent years, with the improvement of people's living standards and the change of the role of pets, the pet economy has flourished, and the pet food market has become more and more popular.

The increasingly popular pet market has also brought us new business opportunities, and the demand for pet food has become larger and more diverse.

Pet food market situation:

The number of pets continues to grow, and the demand for pet food is strong.

Consumers have higher and higher requirements for the quality and safety of pet food.

Personalized and customized pet food has become a development trend.

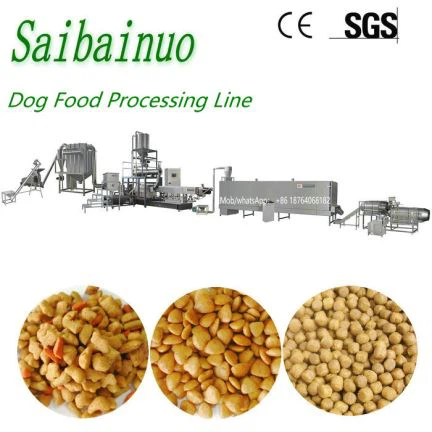

Pet food production line

We mainly use puffing technology to produce pet food. This pet food equipment has a high degree of automation and is easy to operate, so even novices can quickly get started. Modular design can be customized according to your actual needs, flexible and efficient.

For this pet food production line, it mainly including mixing system, extruding system , drying and flavoring, packing,etc.

You can tell us your requirement for our machines, such as capacity, raw materials variety,dryer heating way, packing size, etc. We can provide professional pet food production solutions according to your information.

Technical Parameter of Pet Food Processing Line

Differenet capacity and different configuration of pet food machines for option.

|

Model |

Output |

Power |

Dimension |

|

SLG65-III |

100-150kg/h |

74kw |

23*2*3m |

|

SLG70-II |

200-250kg/h |

120kw |

23*2*3m |

|

SLG85-II |

500-600kg/h |

210kw |

32*3*5.5m |

|

SLG95 |

1-2 ton/h |

290kw |

42*3*5.5m |

Layout of pet food production line

You can tell us your factory size and structure, our technical engineer can design the pet food line according to your factory structure details. In this way, we can maximize the use of workshop space and arrange pet food equipment more reasonably.

Installation and training service

When customer receive our pet food machines, our engineer will fly to customers' factory for pet food machine installation and training service.

Our engineer will help to do machine installation and teach customers' workers how to operate the machines.

The work of engineers mainly includes the following aspects

1. Installation and inspection of pet food manufacturing equipment

Install equipment: Install new pet food equipment according to specifications to ensure correct position, connection and fixation.

Inspect equipment: Confirm that the appearance of the equipment is not damaged, all parts are complete, and the connection is correct.

2. Electrical and mechanical commissioning

Electrical commissioning: Check the electrical system to ensure that the wiring is correct, the voltage and current meet the requirements, and test electrical components such as sensors and switches.

3 . Mechanical commissioning: Check mechanical parts to ensure smooth movement, lubrication, and adjust mechanical parameters such as position and speed.

4. Equipment operation test

No-load operation: Test the equipment without loading materials and check the operation of each component.

Load operation: Test the equipment under actual production conditions to ensure normal operation under load.

5. Optimization and adjustment

Adjust equipment parameters and pet food formula according to test results to optimize production efficiency and quality.

Technical support: Provide follow-up technical support to solve problems in operation.

Jinan Saibainuo Company

Jinan Saibainuo Extrusion Machinery Co.,Ltd has been in this food equipment field more than 30 years,is a high-tech enterprise focusing on the research, development, production and sales of extrusion food machinery and equipment. Jinan Saibainuo is headquartered in Jinan city, Shandong Province, China. It has modern production base and a professional R&D team. We are committed to providing global customers with efficient, energy-saving and environmentally friendly puffed food production machines and supporting equipment, which are widely used in the fields of snack foods, pet foods, nutritional foods, etc.

Core business of Jinan Saibainuo

Puffed food production line: Provide a full set of automated production lines from raw material processing, puffing extruding,drying,flavoring to packaging.

Customized equipment: Customize puffing equipment of different specifications and functions according to customer needs to meet diversified production needs.

Technical support and after-sales service: Provide customers with extrusion food equipment installation, commissioning, operation training and lifelong maintenance services.

If you have any need for our pet food machines, please do not hesitate to contact with us.

Jinan Saibainuo Extrusion Machinery Co.,Ltd

Address: Jinan City,Shandong Province,China.

Contact whatsApp: +86 152 5313 3368

Hot Tags: pet food manufacturing equipment, China, manufacturers, suppliers, price